Talk about the beam lights – Made in China

Current status of beam lights

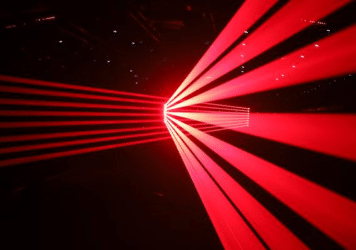

Beam light, also known as sharpy. There are 300W beam light, 700W beam light, 200W beam light, 230W beam light, 260W beam light, 330W beam light, 1500W beam light and other series. 300W beam lights and 700W beam lights became popular around 2010 and have a certain beam feel.

However, in the sense of beam lights, the beam lights that are loved and recognized by everyone began to become popular from 200W beam lights, which became popular in August 2012 and blossomed everywhere in 2012. Since then, it has been continuously updated and developed into 230W beam light, 260W beam light, 330W beam light, and 1500W beam light.

And beam pattern combination lamps. But the mainstream is still 200W beam light and 230W beam light.

Working principle of beam light

Beam lights mainly rely on their unique light source to become famous. Its unique small-diameter cup bubble design and focal length positioning principle enable high light efficiency utilization. Its high lumens also lead to high calorific value, which also leads to the high burst rate of early-rising 200W beam lamps. Therefore, the heat dissipation of this beam light is different from that of traditional computer moving head lights. Its wick is relatively thin and there is no peripheral isolation layer. Therefore, if it dissipates heat like traditional lamps, that is, the bigger the heat dissipation, the better, it is not possible. Yes, this will cause the ionization arc of the bulb to continuously ionize, affecting the life of the bulb. If there is not enough heat dissipation, the bulb will explode quickly. Therefore, this beam light requires a constant temperature system.

Currently, Chinese manufacturers have two cooling solutions. One is traditional cooling, which relies on better fans to dissipate light bulbs and cooperates with temperature control switches. Another better method is software temperature control and heat dissipation, which relies on software to control the constant temperature of the fan. If the fan slows down or fails, the bulb will be automatically extinguished to prevent it from exploding. The latter of the two methods is better, even if the former does not explode, it will have a greater impact on the life of the bulb. Beam light bulb categories: Beam light bulbs are mainly made by Philips. There are four categories here. One is the original bulb, namely Philips Platinum 5R bulb MSD or the more commonly used Osram original 230W bulb. The other is Philips UHP bulb. Taiwan’s Youdeng 5R is widely used in the market. One type is various fake bubbles and bubbles with uneven color temperature and uneven brightness screened out by Philips. The original 5R platinum foam is about 700 more expensive than the UHP. In addition, the same UHP bulbs have different bubble pressures. Good manufacturers will measure the bubble pressure and screen the bulbs again to ensure the stability and consistency of the bulbs.

Beam light development path and latest technology in 2024

Increase in brightness and color temperature:

With the gradual application of light source technologies such as halogen bulbs and high-brightness LEDs, the brightness of beam lights has been significantly improved. At the same time, the dimmable LED light source also provides more flexible control options for beam lights, making the lighting effects more diverse.

Introducing CMY+CTO technology:

The introduction of CMY+CTO technology marks further innovation in beam lamps. The CMY color system allows for a wider range of color variations, while CTO provides more precise control of color temperature. The application of this technology enables beam lights to better adapt to the lighting needs of different scenes and achieve more detailed lighting designs.

Intelligent and programmable control:

With the intelligent development of stage lighting technology, beam lights are gradually adding programmable control systems. Through standard protocols such as DMX512, lighting designers can precisely control the brightness, color, movement and effects of each lamp to achieve more sophisticated and complex lighting performance.

Multifunctional and multi-effect design:

Modern beam lamps usually integrate multiple functions and effects, such as rotation, zoom, pattern projection, etc. These designs make beam lights an indispensable tool in stage lighting design, capable of creating colorful light and shadow effects and enhancing the visual impact of stage performances.

At the LDI booth at the end of 2023, major brands showed that the future development direction of beam lights is mainly to be more intelligent, easier to combine with smart devices, and get rid of traditional console settings and controls. In addition, the details of dimming are more professional, lower cost, lighter, more effective and lower noise. For a long time, LED light sources will be the mainstream.

What is the quality of beam lights made in China?

Clearly, it all depends on the manufacturer. Quality can vary greatly across the board with these units.JCLIGHT adheres to the principle of stability and constantly lights up the technology tree while ensuring product quality and cost performance. At present, most of the products are in line with international mainstream products. While ensuring the same quality, our prices are lower. The effect is stronger. At the end of the article, some latest product cases of beam lights are included.

800/1000/1200/1400W CMY+CTO 4 IN 1 WATERPROOF LED COMPUTER CUT MOVING HEAD LIGHT

Leave a Reply